This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Surface Treatments

Inflite’s NadCap approved surface treatment Facility (Aerospace Surface Treatments or AST) provides essential surface treatments, anodising, mask and paint finish, and NDT to both Inflite engineering and its own dedicated customer base.

Having undergone £1.2m of investment in 2019, allowing AST to become a key player in the surface engineering industry. Offering a vast range of NDT and surface engineering approvals, its name has become synonymous with service times and quality within the industry.

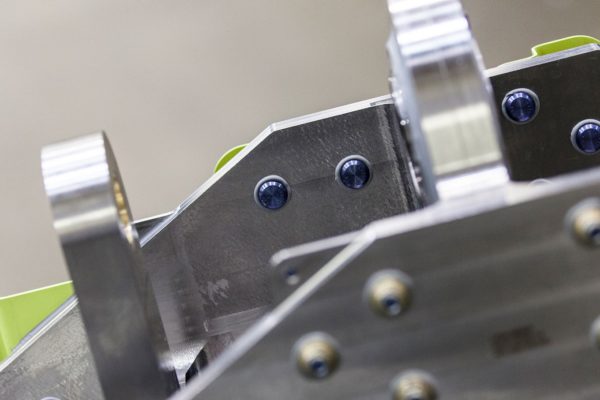

AST have two dedicated treatment lines with tanks 6ft and 12ft in length. We have operators running two lines which include cleaning, pickling, passivation, chromate, along with varied anodising processes. We currently offer three anodising technologies: Chromic acid anodising (CAA), Sulphuric acid anodising (SAA), and Tartaric Sulphuric Anodising (TSA).

We offer three chromate conversion systems: Bonderite M-CR1200, a coloured coating formally known as Alocrom 1200, Bonderite M-CR1001, a clear chromate conversion system that replaced the Alocrom 1000 process and SurTec 650 Chromium (VI)–free trivalent passivation for aluminium. AST also provide a range of treatments for stainless steels and titanium. Included in these are both chromated and non-chromated stainless steel passivation systems, as well as pickles for both stainless steel and titanium alloys.

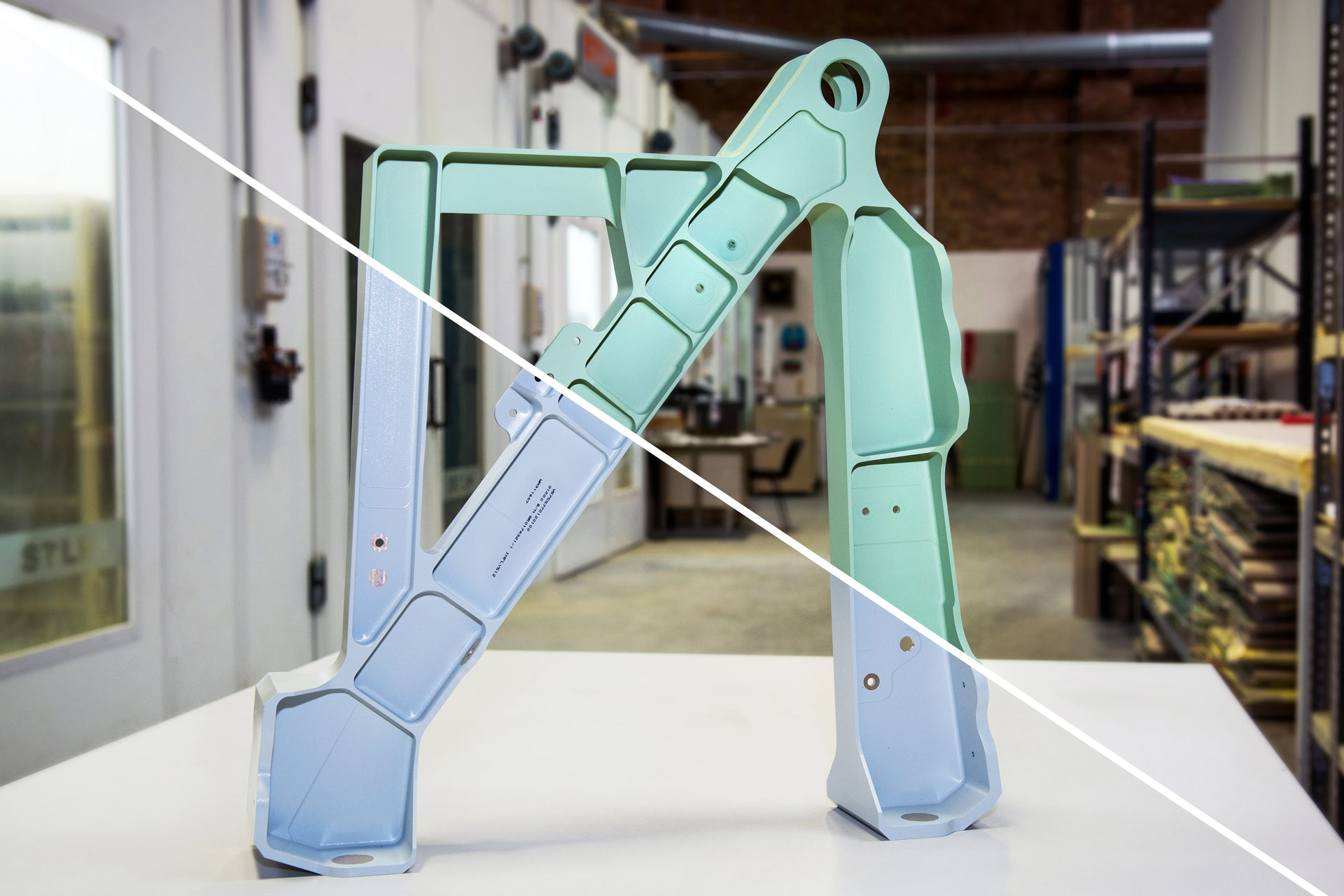

To finish the components we have a large preparation facility with in-house die-cutting and masking team. Masking is completed before both wet treatments and spray coating. Having recently undergone a large investment into its paint facilities, AST can offer Prime and Top Coat finishes to a high standard in its 4 new spray booths.

For component identification, inkjet ident system and computer controlled vibro engraver are used.

AST provides the finish touches to the majority of components manufactured by Inflite, adding yet another list of processes that can be completed in-house within the Inflite Group.